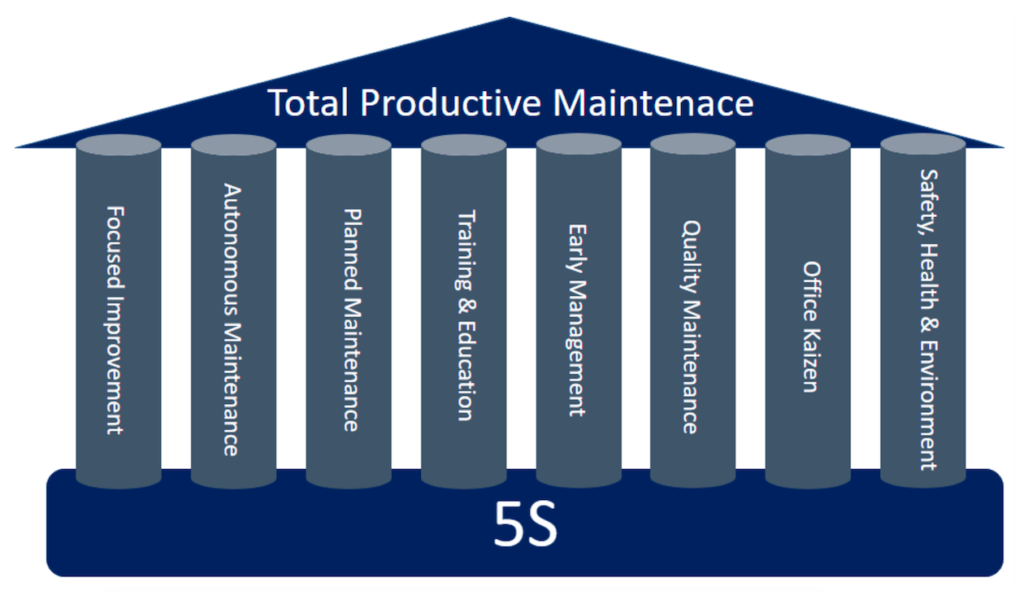

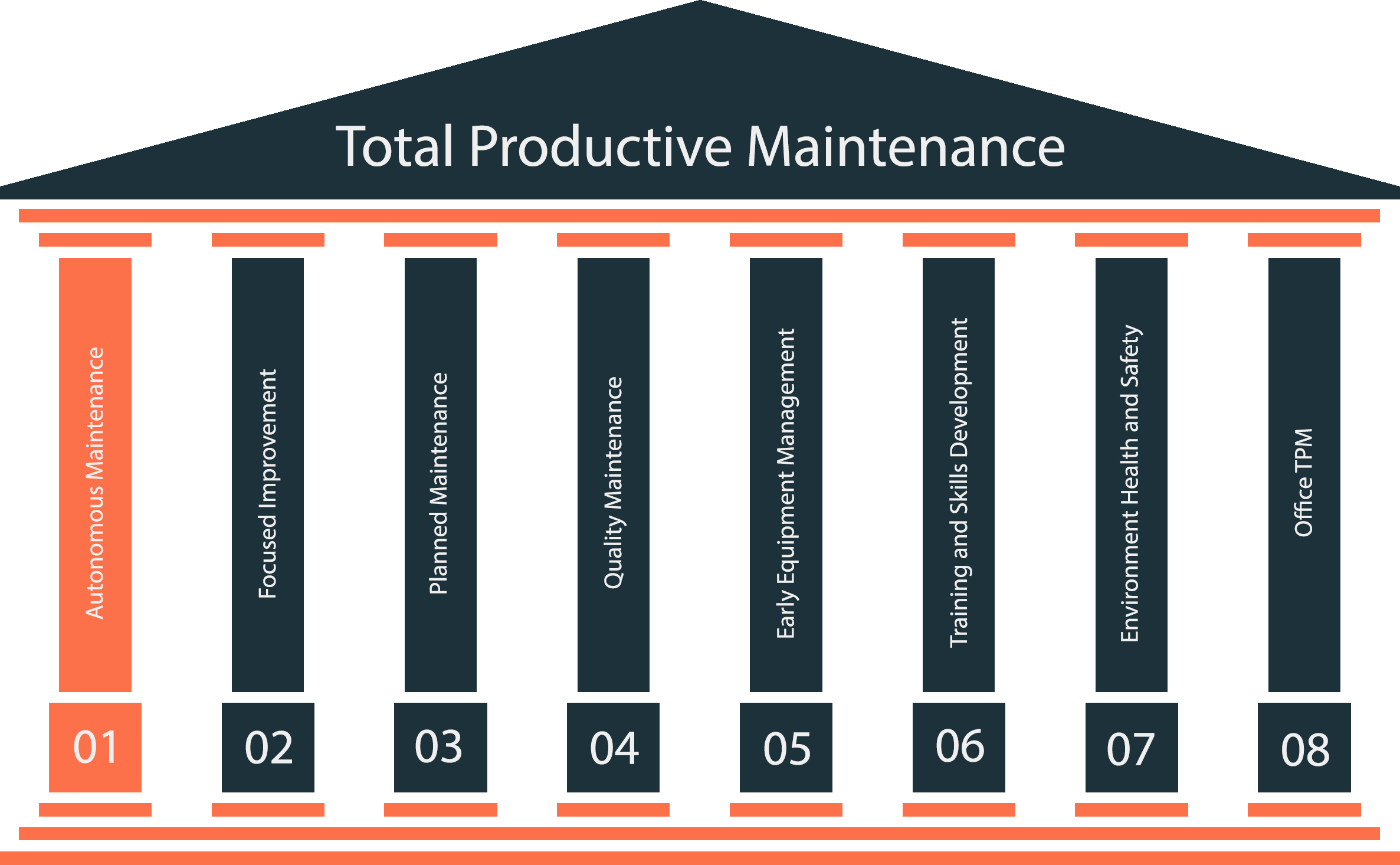

Total Productive Maintenance Methodology Total Productive Maintenance is an interconnected approach to equipment maintenance that aims to achieve perfect production availability of equipment by minimizing inefficiencies accidents

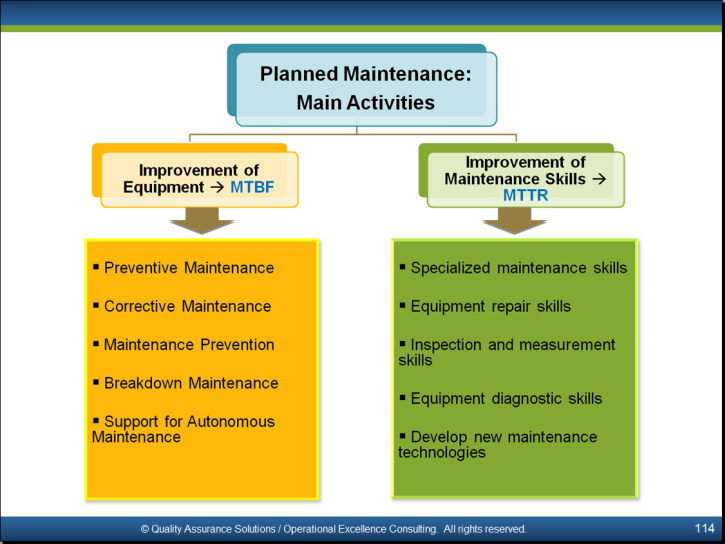

What is Total Productive Maintenance TPM Total productive maintenance is a complete system for maintenance of equipment that aims at achieving an optimal production Total Productive Maintenance TPM is a method aimed at maintenance management It consists of a series of recommendations grouped together by the Japan

Total Productive Maintenance Methodology

Total Productive Maintenance Methodology

https://leanmanufacturing.online/wp-content/uploads/2022/05/Total-Productive-Maintenance-1024x591.png

Total Productive Maintenance TPM And Its Pillars Learn 58 OFF

https://www.micromain.com/wp-content/uploads/eight-pillars-total-productive-maintenance.png

Total Productive Maintenance TPM And Its Pillars Learn 58 OFF

https://learntransformation.com/wp-content/uploads/2023/06/pfi-tpm-total-productive-maintenance-19082022.webp

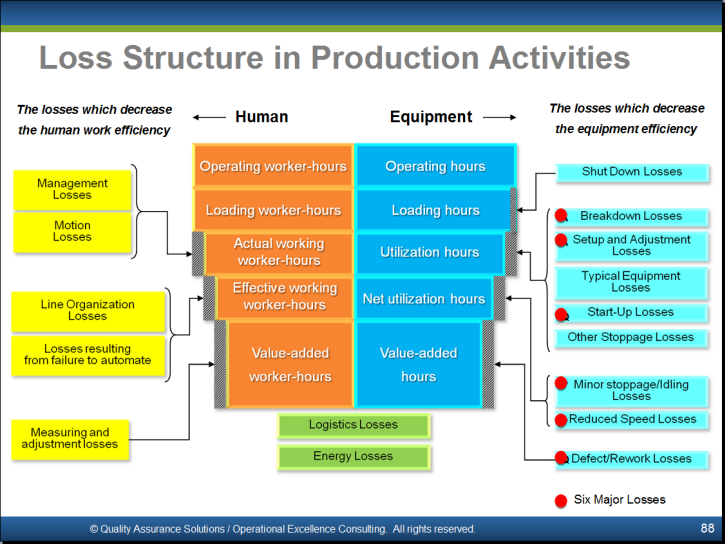

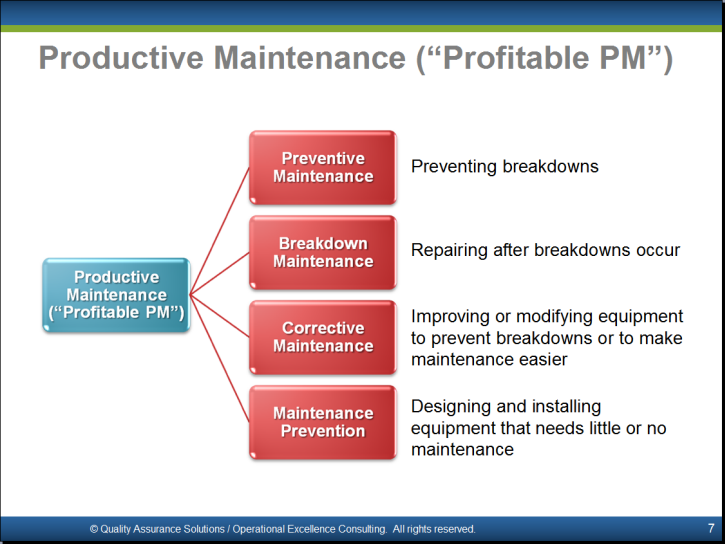

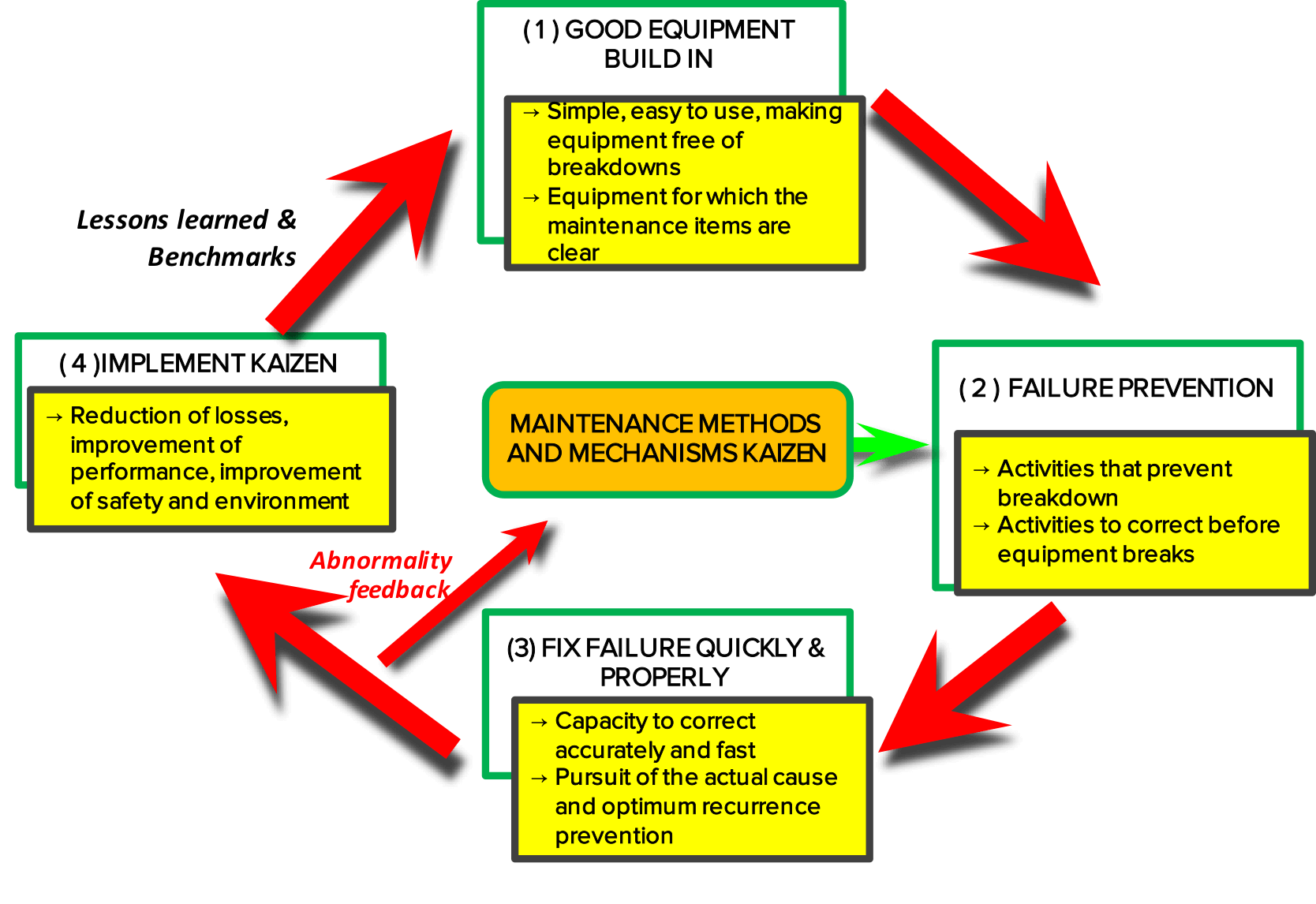

Total productive maintenance TPM started as a method of physical asset management focused on maintaining and improving manufacturing machinery in order to reduce the operating cost Total Productive Maintenance TPM seeks to engage all levels and functions in an organization to maximize the overall effectiveness of production equipment This method

TPM stands for Total Productive Maintenance It is an industrial maintenance management methodology originating in Japan specifically Nippon Denso Toyota s electronic components Total productive maintenance TPM is a method of maintaining and improving the integrity of production and quality systems through the machines equipment employees and

More picture related to Total Productive Maintenance Methodology

Total Productive Maintenance PowerPoint Template Total Productive

https://i.pinimg.com/originals/82/c2/08/82c208ccf202da295e061fbb2cfccff4.png

Total Productive Maintenance

https://trainingyogyakarta.com/wp-content/uploads/2016/08/Total-Productive-Maintenance.png

Tpm 2025 Dates Debera Anselma

https://www.symbios-consulting.com/images/whyTPM.png

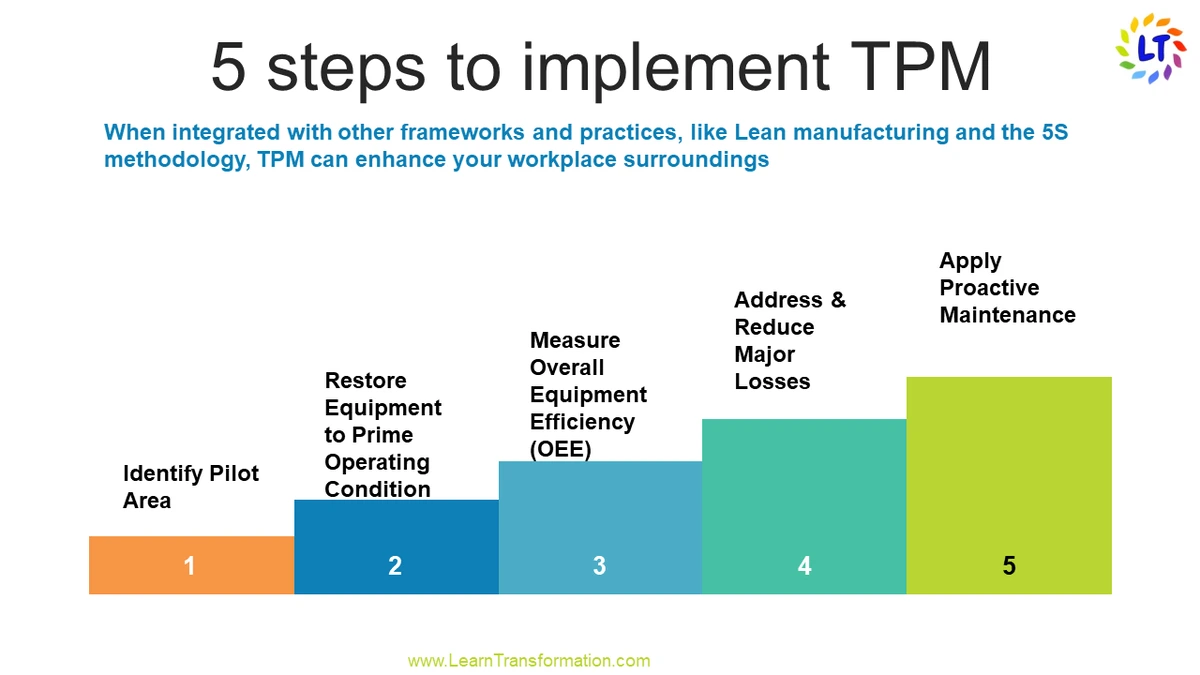

Total Productive Maintenance or TPM is a proven methodology used to optimise and increase machine productivity It comprises a systematic maintenance program that involves an Total Productive Maintenance TPM is a structured approach that helps businesses optimize equipment performance minimize downtime and enhance overall

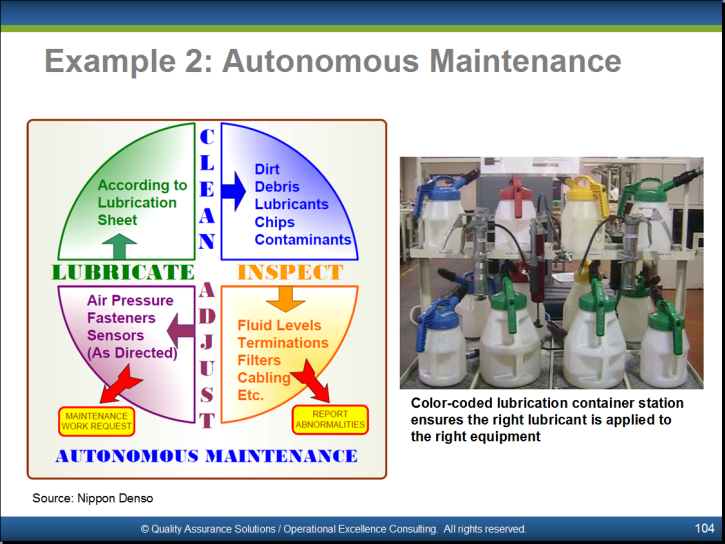

Let s delve into each one 1 Autonomous Maintenance Empower frontline workers to take charge of basic maintenance tasks fostering a proactive approach to upkeep Total productive maintenance TPM is a methodology designed to improve production systems by preventing problems Its goal is to improve product quality minimize

TPM Visual Management

https://media.noria.com/sites/Uploads/2019/8/15/f06e329e-6471-4e85-b9f0-a5c6e681e4b0_TPM-5steps-600w_extra_large.jpeg

Steps

https://industryforum.co.uk/wp-content/uploads/sites/6/2016/09/12-steps.gif

https://www.learnleansigma.com › guides › total...

Total Productive Maintenance is an interconnected approach to equipment maintenance that aims to achieve perfect production availability of equipment by minimizing inefficiencies accidents

https://leanfactories.com › tpm-pillars-eight...

What is Total Productive Maintenance TPM Total productive maintenance is a complete system for maintenance of equipment that aims at achieving an optimal production

Total Productive Maintenance PowerPoint

TPM Visual Management

Total Productive Maintenance PowerPoint

Total Productive Maintenance PowerPoint

Total Productive Maintenance PowerPoint

Everything You Need To Know About Autonomous Maintenance Limble

Everything You Need To Know About Autonomous Maintenance Limble

TPM In Field Training

TPM Lean Manufacturing

What Is Autonomous Maintenance And How To Implement Augmentir

Total Productive Maintenance Methodology - Total Productive Maintenance TPM is a maintenance program which involves a newly defined concept for maintaining plants and equipment The goal of the TPM program is to markedly